Table of Contents

Intro

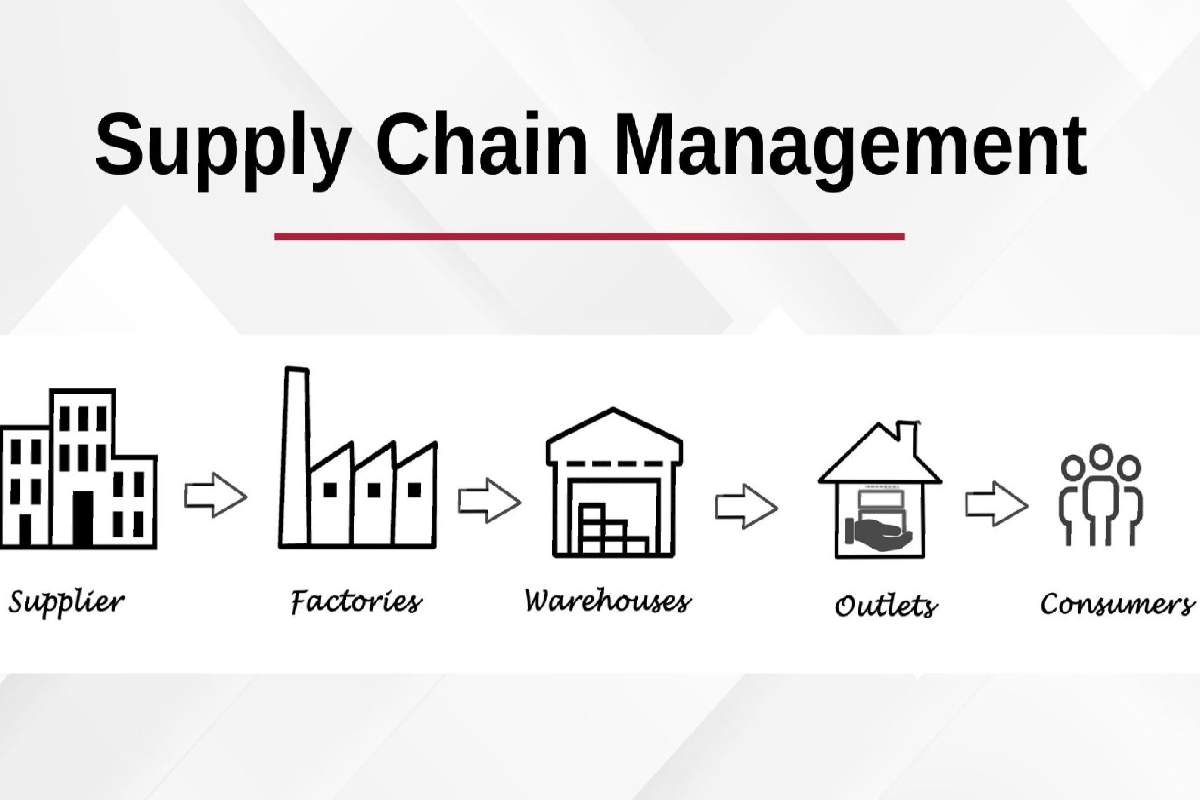

A complicated and organized system called technologies to scale supply chain management is employed to get customers high-quality and reasonably priced items. To ensure the highest level of satisfaction, it maintains businesses are running smoothly and efficiently while fostering customer-centric operations.

Due to new technologies, supply chain management is changing, and successful business growth now depends on real-time tracking and precise, quick deliveries. It might be challenging for big businesses to integrate supply chain management systems.

A new manufacturing era is being ushered in by handheld devices, digital transformation, and competitive operating methods, but the benefits are indisputable. The Impact of Technologies on Scale Supply Chain Management

Improved Supply Chain Communication

- Without sufficient and efficient communication, supply chain management will fail. These intricate networks depend on synergy and numerous codependent or reciprocal components.

- Communication is essential for tying together each link in the production chain and ensuring smooth operations free from hiccups that might compromise the final product’s overall quality.

- The immediate communication between workers and managers, as well as constant visibility of every aspect of manufacturing from the warehouse to deliveries to corporate tasks maintains all operations’ simultaneity, speed.

- And accuracy, achieving maximum productivity and eliminating needless waste or lulls, which ultimately results in a satisfied customer.

- Additionally, the organization can speed up fulfillment rates, which equates to quick service, contented customers, and higher revenues.

- It is made possible by optimized communication with mobile devices, voice-based instructions, scanners, location trackers, and monitoring capabilities that allow immediate solutions to hiccups in the chain.

Greater Efficiency in Supply Chain Processes

- To automate manufacturing processes, operational efficiency, safe information transfer, and supply chain effectiveness can be improved using digital equipment, including software than hardware solutions.

- Increasing collaborative efforts through system integration ensures that operations continue to be quick and seamless.

- Time and resources are saving through prompt responses to chain breaks, which boosts output and results.

- Instantaneous data gathering and analysis enable quick judgments and answers, identifying issues and addressing them before a significant breach happens somewhere in the manufacturing process, from concept to warehouse to client’s hands.

- Additionally, data collecting is safe, precise, and storable with handheld mobile devices and automated procedures.

- Assisting manufacturers in streamlining their operations with more effective and efficient approaches.

More Transparency in Supply Chain Visibility

- Consistency is crucial to deliver a presentable and commendable product that is consistent with the company brand. Transparency is crucial for ensuring proper and reliable operation handling.

- Employees and managers can easily access current visibility, allowing them to intervene as needed to protect the finished product.

- Consumers may check on the progress of supplies and participate in the production process thanks to transparency. Which also extends to them.

- Customization and instructions sent directly to the manufacturer keep the customer informed and ensure they will receive a product that matches their specific requirements and that they will be happy to possess.

- With better visibility made possible by supply chain technology, manufacturing leaders and customers know exactly what to expect.